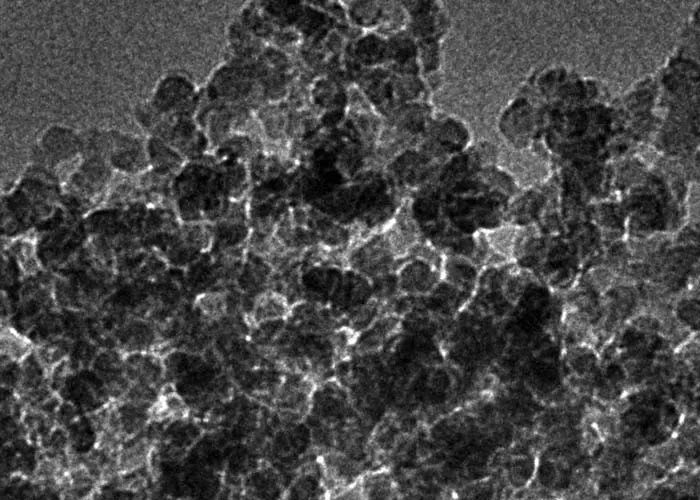

99.5% Purity 30nm Nano Silica Powder,Nano SiO2 NS-W-SP30T

| Appearance: | White Powder | Grain Size: | 30 ± 5nm |

| Purity: | SiO2 > 99.5% | S.S.A.: | 150 - 300 M2/g |

| PH: | 5-7 | ||

| High Light: |

nano sio2, nano silicon dioxide |

||

Parameters Table:

Nanometer Silicon Dioxide (Nano SiO2)

NS-W series

Property:

Small pariticla size,high purity,big BET.

Obviously improve the stability of dope.

Perfect flow-linked performance.

Good adhesion strength and thixotropy.

Greatly improve the toughness and surface finish of dope.

Specifications:

|

Type |

Appearance |

Grain size(nm) |

SiO2(%) |

S.S.A.(m2/g) |

PH |

Remark |

|

NS-W-SP15 |

White powder |

15 ± 5 |

99.8 |

250 ± 30 |

3 - 6 |

Big specific surface area, high transparency |

|

NS-W-SP20 |

White powder |

20 ± 5 |

99.5 |

180 ± 30 |

7 - 8 |

Porous, good thickening effect,wear -resistant and hard increasing for coating |

|

NS-W- SP30 |

White powder |

30 ± 5 |

99.5 |

150 ± 30 |

7 - 8 |

Good dispersion, wear -resistant and hard increasing for coating |

|

NS-W- SP50 |

White powder |

50 ± 5 |

99.5 |

50 ± 30 |

7 -8 |

Good dispersion, wear -resistant and hard increasing for coating |

|

NS-W-SP30H |

White powder |

30 ± 5 |

99.5 |

150 ±30 |

7 - 8 |

Hydrophilic, good dispersion in water,for Paint, latex, paper |

|

NS-W-SP30T |

White powder |

30 ± 5 |

99.5 |

150 ±30 |

7 - 8 |

wear -resistant and hard increasing for coating and painting |

|

NS-W-SP30S |

White powder |

30 ± 5 |

99.5 |

150 ±30 |

-- |

lipophilic, wear -resistant and hard increasing for Paint, plastic, rubber, ink |

|

NS-W-SP30F |

White powder |

30 ± 5 |

99.5 |

150 ±30 |

7 - 8 |

Good dispersion, high activity,for spinning; |

|

NS-W-SP30K |

White powder |

30 ± 5 |

99.5 |

220 ± 30 |

6 - 8 |

For printing ink |

|

NS-W-SR01 |

White powder |

30 ± 5 |

99.5 |

150 ± 30 |

7 - 8 |

Improve strength and toughness, anti - aging, anti - friction fire, prolong life for rubber |

|

NS-W-SH30 |

White powder |

30 ± 5 |

99.5 |

150 ± 30 |

7 - 8 |

For concrete |

|

NS-W-SP30B |

White powder |

30 ± 5 |

99.5 |

200 ± 30 |

7 - 8 |

For matting agent |

Application:

Applications:

For rubber: improve intensity,tenacity,anti-aging,re-attrite and so on.

For plastic: improve the intensity,tenacity and anti-aging capabilities of plastic.

For epoxy resin: improve rigidity,intensity,tenacity,high temperature resistance and anti-aging capabilities.

For dope: greatly improve suspension property,thixotropic,weatherability,anti-washing and anti-infra-red.

For gooey and sealant: improve the ropy of gooey and the sealed ability of sealant.

For other industries: used in electronic encapsulation,polymer of macromolecule,paint,adhesive,functional fiber,cosmetics and many more applications.